Product introduction

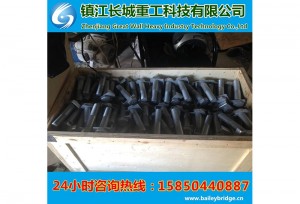

1.Truss bolts

Truss bolts M36 X 250; Used to connect the upper and lower trusses. When in use, insert the bolts from the bottom to the top into the bolt holes of the truss chord, so that the bent backing plate of the bolt is stuck in the chord, and the nut is tightened.

Chord bolt

Specifications

1 To support Bailey decking System

2 To connect chords and panels

3 Commonly used in steel bridge

4 Bailey bridge

Chord bolt M36 X 180, the shape is the same as the truss bolt, only 7 cm shorter in length. It is used to connect the truss and the reinforced chord. During installation, as shown in the figure below, the head of the screw is buried in the reinforced chord to prevent the bridge from being blocked when the bridge is pushed out.

Product function

The role of chord bolts and truss bolts is mainly to strengthen the connection between the chord and the upper and lower chords of the truss.

The Bailey bridge is a type of portable, pre-fabricated, truss bridge. It was developed by the British during World War II for military use and saw extensive use by both British and the American military engineering units.

A Bailey bridge had the advantages of requiring no special tools or heavy equipment to assemble. The wood and steel bridge elements were small and light enough to be carried in trucks and lifted into place by hand, without requiring the use of a crane. The bridges were strong enough to carry tanks. Bailey bridges continue to be extensively used in civil engineering construction projects and to provide temporary crossings for foot and vehicle traffic.

The success of the Bailey bridge was due to its unique modular design, and the fact that one could be assembled with minimal aid from heavy equipment. Most, if not all, previous designs for military bridges required cranes to lift the pre-assembled bridge and lower it into place. The Bailey parts were made of standard steel alloys, and were simple enough that parts made at a number of different factories could be completely interchangeable. Each individual part could be carried by a small number of men, enabling army engineers to move more easily and more quickly than before, in preparing the way for troops and matériel advancing behind them. Finally, the modular design allowed engineers to build each bridge to be as long and as strong as needed, doubling or tripling up on the supportive side panels, or on the roadbed sections.